日本語 | English

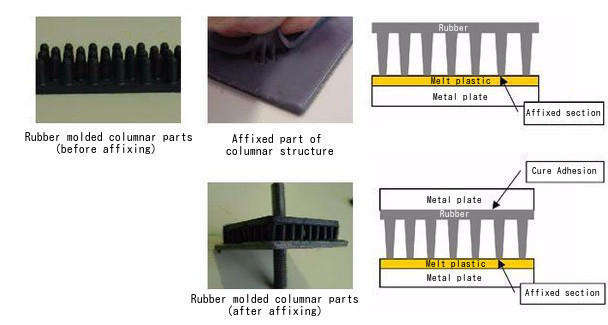

Melt Stick Rubber Method (Patented)

This method fixes acicular solid rubber on melt plastic to create a rubber structure with internal space. It allows for the development of functional products without the problems related to the softness of solid rubber, weak properties of sponge, and limit to repulsion force and durability.Features of Melt Stick Rubber Method

1.Adjusting hardness of solid rubber, height and thickness of acicular structure allows for wide-ranging repulsion force.It also provides the impact absorption function of cushion material.

2.Outstanding durability with very little surface damage from repeated bumping.

※When developing products utilizing the elasticity of solid rubber, the hardness suitable for mass production is between 40 and 90 degrees.

If further softness is required, sponge (foam material) must be used.

However, the surface layer of sponge (foam material) had poor durability and the surface layer deteriorates with long-term use.

Moreover, when repulsion force is sought, there is a limit with lowered rubber properties from added foam.

Use

1.Impact and vibration absorption parts for automobiles, motorcycles, boats, and train carriages, etc.2.Vibration absorption parts for motor parts in industrial, construction, farming and engineering machines, etc.

3.Impact absorption parts, sound insulation parts and vibration absorption parts for residential homes and facility furniture

4.Impact absorption parts and seismic isolation parts for civil engineering

5.Impact and vibration absorption parts for household appliances and OA equipment